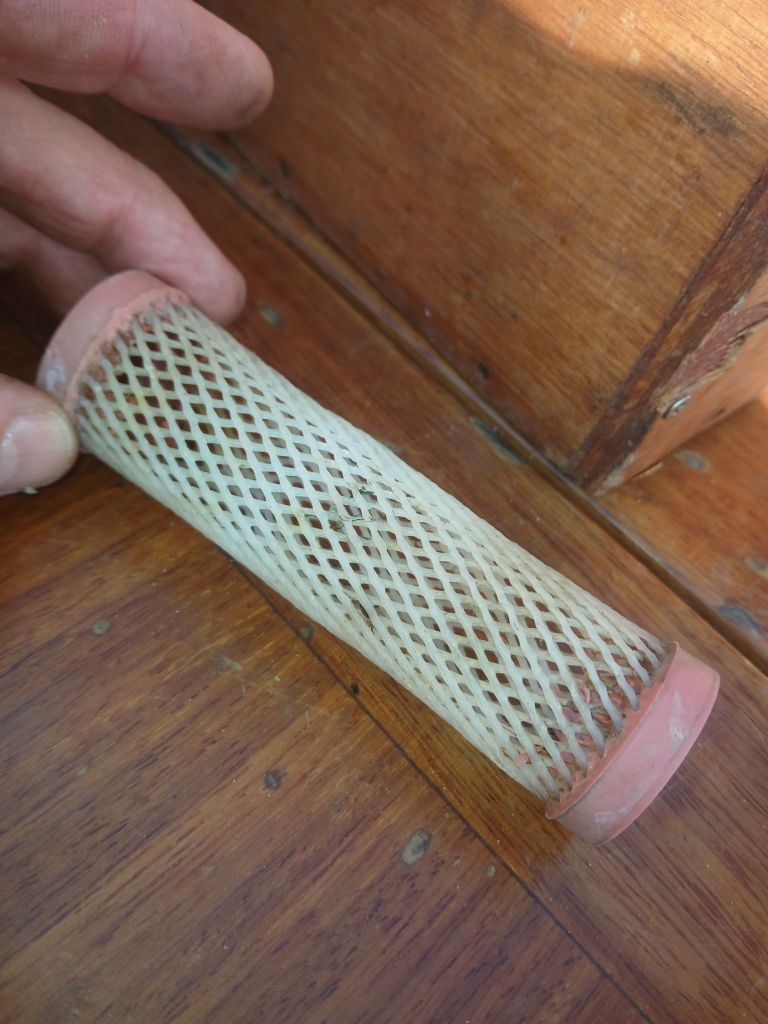

While I had the floor up I checked a few items that need regular maintenance. The water pump pushes water into the exhaust pipe for cooling purposes. Checking the grease pot. Taking the access plate off to check the condition of the pump impeller and checking the water inlet filter.

Checking the speed log impeller

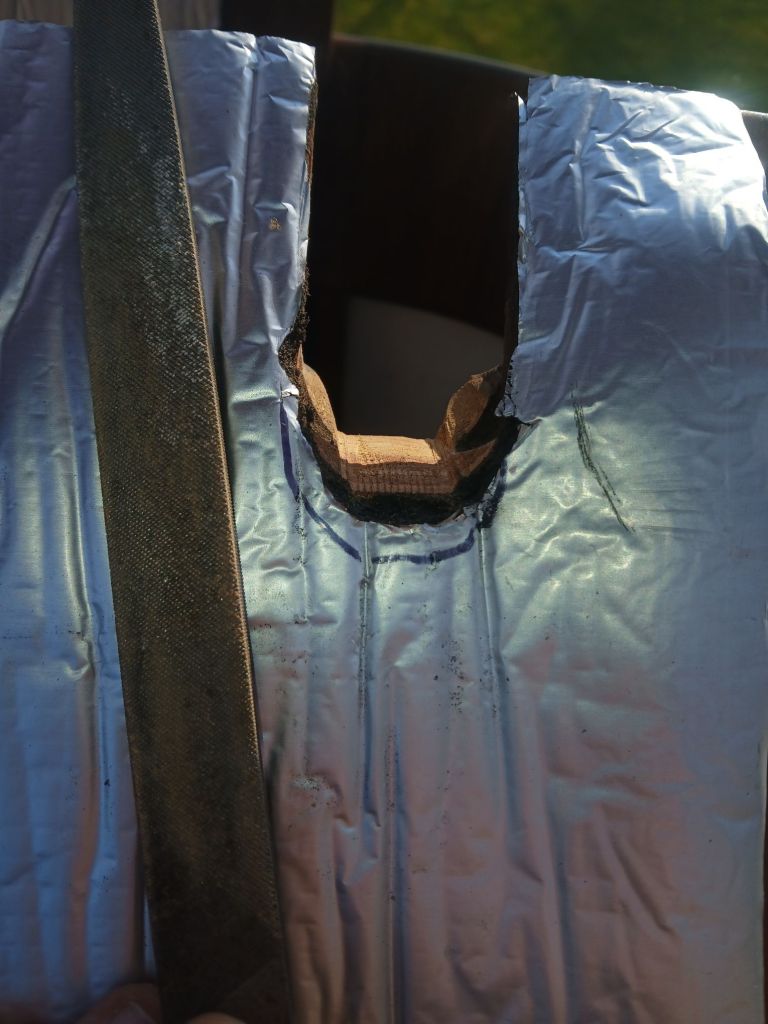

Small adjustment to the engine casing where the drive pulleys have come into contact with the wood. Inspecting the parts I realised if I extended the U shaped cutout it might break through the moulding to the outside surface. I checked the pulley tensioner to see if that could be relaxed enough to prevent contact but felt this might compromise the belt tension. I opted to just change the shape of the cutout to more of a square shape using a file and that seemed to give enough clearance in the end.

Engine test.

Leave a comment